General or common overhead costs like rent, heating, electricity are incurred as a whole item by the company are called Fixed Manufacturing Overhead. Over the year, the company sold 50,000 units and produced 60,000 units, with a unit selling price of $100 per unit. This streamlining improves the accuracy of financial reporting and enhances the visibility of cost components, reducing manual errors and time-consuming processes. Moreover, due to the existence of fixed expenses, an increase in output volume usually results in a lower unit cost. Absorption expenses are easy to track because small businesses often do not have a large number of things.

- Absorption costing has some limitations, and it can be challenging to assess the impact of changes in production levels on profitability since fixed overhead costs remain constant.

- Absorption costing involves accounting for all production-related costs, ensuring a comprehensive allocation to each unit produced.

- Learn through real-world case studies and gain insights into the role of FP&A in mergers, acquisitions, and investment strategies.

- This distinction should be implemented in order to construct a flexible budget.

- Even overhead expenditures that can’t be directly traced to the product are charged against each unit.

- Generally accepted accounting principles require use of absorption costing (also known as “full costing”) for external reporting.

How does absorption costing compare to other methods?

The main difference between absorption costing and variable costing is how they treat fixed manufacturing overhead costs. In absorption costing, fixed manufacturing retained earnings overhead costs are included in the product cost, while in variable costing, all fixed manufacturing overhead costs are treated as period costs. This means that in absorption costing, every product manufactured in a specific period has a portion of the fixed manufacturing overhead costs included in its product cost. In the competitive realm of the service industry, absorption costing shines as a robust tool for financial management. This method mandates including all manufacturing costs in the product’s price – direct materials, labour, and both fixed and variable overheads are essential components of absorption costing. The direct costs of producing one chair are ₹400 for materials and ₹100 for labor.

Under absorption of overhead

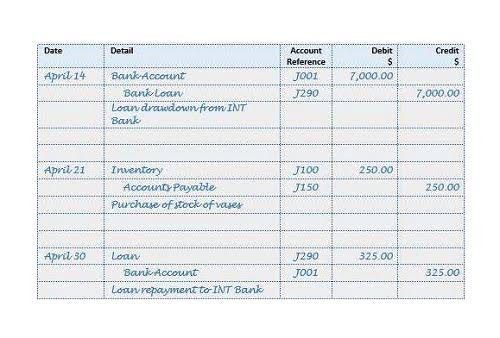

Period costs include all overheads related to the organization, sales, and distribution. To put it another way, all manufacturing costs are absorbed into the price of the finished goods. In this journal entry, the under absorption amount of overhead is the difference between the absorbed overhead and the actual overhead. However, it is opposite from the over absorption of overhead above as the absorbed overhead in this case is lower than the actual overhead. The absorption costing, on the other hand, absorption costing formula will show slightly higher profits.

Gain clear reporting insights

At the same time, accurate absorption costing boosts the value of inventory by valuing it at full production cost. Absorption costing involves accounting for all production-related costs, ensuring a comprehensive allocation to each unit produced. This method provides a detailed breakdown of costs, creating an accurate basis for pricing and financial reporting. Absorption costing is an accounting method that allocates all production costs, both direct and indirect, to individual products.

- Here’s what you need to know about absorption costing and how to apply it in your business.

- Suppose we have a fictional company called XYZ Manufacturing that produces a single product, Widget X.

- The full costing approach helps a company find appropriate and competitive product pricing.

- From gross profit, variable and fixed selling, general, and administrative costs are subtracted to arrive at net income.

- Depreciation is considered a fixed cost in absorption costing because it remains constant regardless of production levels.

Variable costs can be more valuable for short-term decision-making, giving Debt to Asset Ratio a guide to operating profit if there’s a bump-up in production to meet holiday demand, for example. One of the major drawbacks of absorption costing is that it can sometimes distort profit figures. This is because fixed costs are spread across all products, regardless of how much each product actually contributes to covering those costs.

However, these costs are not included in the calculation of product cost per the AC. Keeping your absorption costing method consistent across all of them is important for accurate overall reporting. This characteristic of absorption costing can lead to differences in reported profits compared to variable costing, especially when there are changes in production levels and inventory levels. Maybe calculating the Production Overhead Cost is the most difficult part of the absorption costing method. The following is the step-by-step calculation and explanation of absorbed overhead in applying to Absorption Costing.